Washing area

Individual or collective

Design, production, maintenance

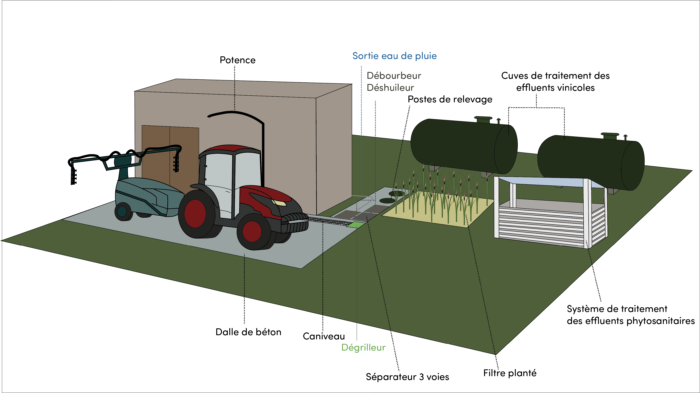

We design and carry out "turnkey" washing areas. They make it possible to recover the wastewater from the rinsing of sprayers and / or harvesting machines in order to store or treat it to comply with the legislation and avoid any environmental pollution. You can also recover rainwater by installing a flow separator.

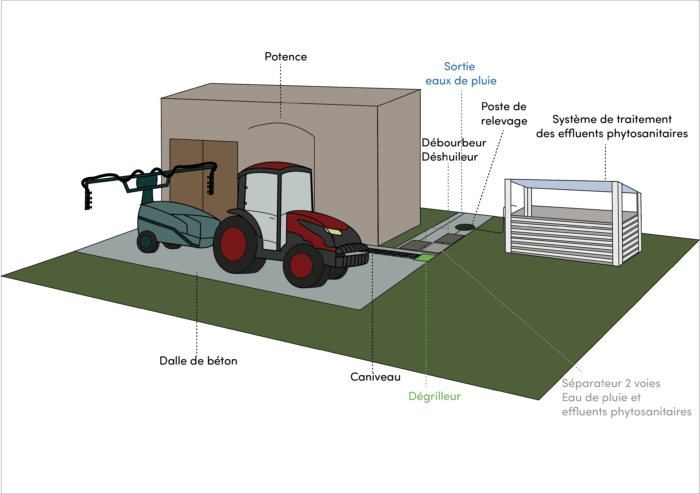

Sprayers washing area

Phytosanitary wastewater treatment

This washing area makes it possible to recover the wastewater from rinsing the sprayer in order to temporarily store it or treat it on site. Therefore, the area is equipped with a flow separator with two paths (PVC pipes, valves or guillotines) which will make it possible to separate phytosanitary wastewater from rainwater. The waters containing the phytosanitary wastewater will pass through an oil separator and a sludge trap to finally arrive by gravity in a buried storage tank or towards the phytosanitary wastewater treatment system via a lifting station.

The treatment system we install is called Phytobarre. It is an innovation from the Adéquabio company which makes it possible to treat phytosanitary wastewater thanks to a simple and effective technology: water evaporation and a bacterial treatment. The advantage of this system is that it does not require any handling of toxic product for more than 10 years.

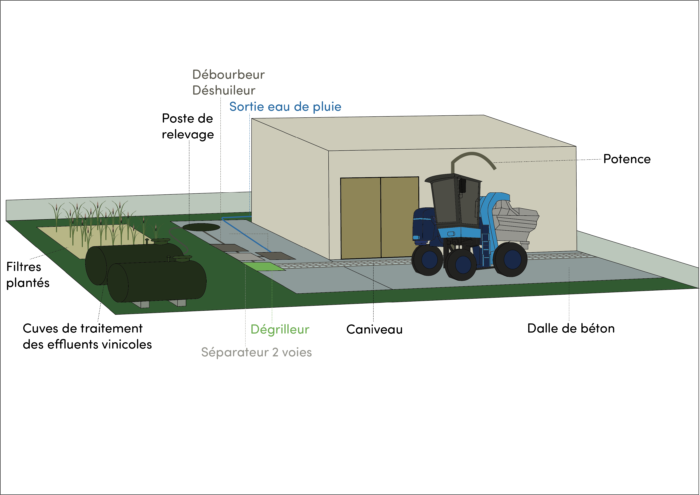

Harvesting machine washing area

Winery wastewater treatment

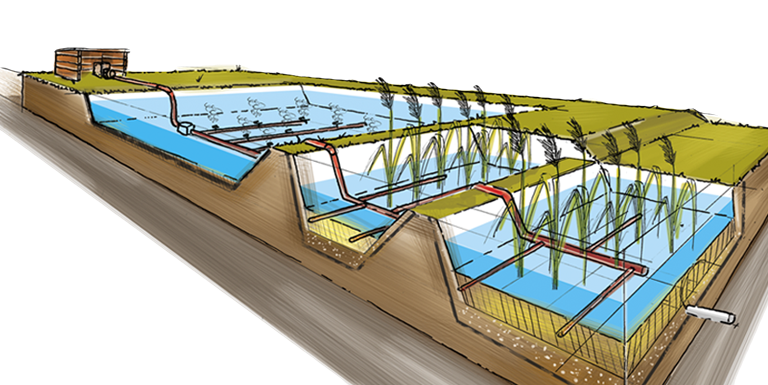

This washing area makes it possible to recover the wastewater from rinsing the harvesting machine in order to temporarily store it or treat it on site. Here, the area is also equipped with a flow separator with two paths which will allow the wine wastewater to be separated from rainwater. Before their discharge into the natural environment or their storage, rainwater will be cleaned by passing through an oil separator / sludge trap. The wastewater will be sent by gravity to a storage tank or to the Clairéo wine wastewater treatment system. Depending on the configuration of each wine-growing holding, a study may be carried out to define the interest or not to bury the tanks as well as the need or not for a lifting station.

Our wine wastewater treatment process is 100% natural and stands out for its simplicity of implementation and operation.

Mixed washing area

storage or treatment

The washing area can also be used for both types of wastewater. In this case, we will install a 3-way flow separator to separate phytosanitary wastewater, winery wastewater and rainwater.

We can install this type of washing area to store the effluents or to treat them directly thanks to our systems.

Collective washing area

These areas can also be created for a collective need. We therefore offer, as an option, a badge access control system, to ensure the exclusivity of the area for the users concerned. In order to ensure ease of operation, we recommend in some cases the installation of an automatic screen screen which eliminates the need for daily manual intervention during the harvest.

Our commitment

- We design with you the washing area so it best meets your expectations (field study, location, plans).

- We take care of all the implementation work (by coordinating the work of our specialized partners by trade) until commissioning.

- A number of options can be offered to you such as the motorization of the separation valves, the installation of a volume counter for filling sprayers, setting up automatic screens, lighting ...

Winery and phytosanitary wastewater treatment systems used

Clairéo Solution – Winery wastewater treatment

Natural winery wastewater treatment systems

Read more